TECHNICAL CONSIDERATIONS

TECHNICAL CONSIDERATIONSRaw water supply for industrial processes and utilities can be drawn from many sources ranging from high quality municipal water that has already been treated to a drinking water standard through to untreated surface and ground waters. Raw water quality will vary widely depending on the source and what impurities the water has picked up from the environment.

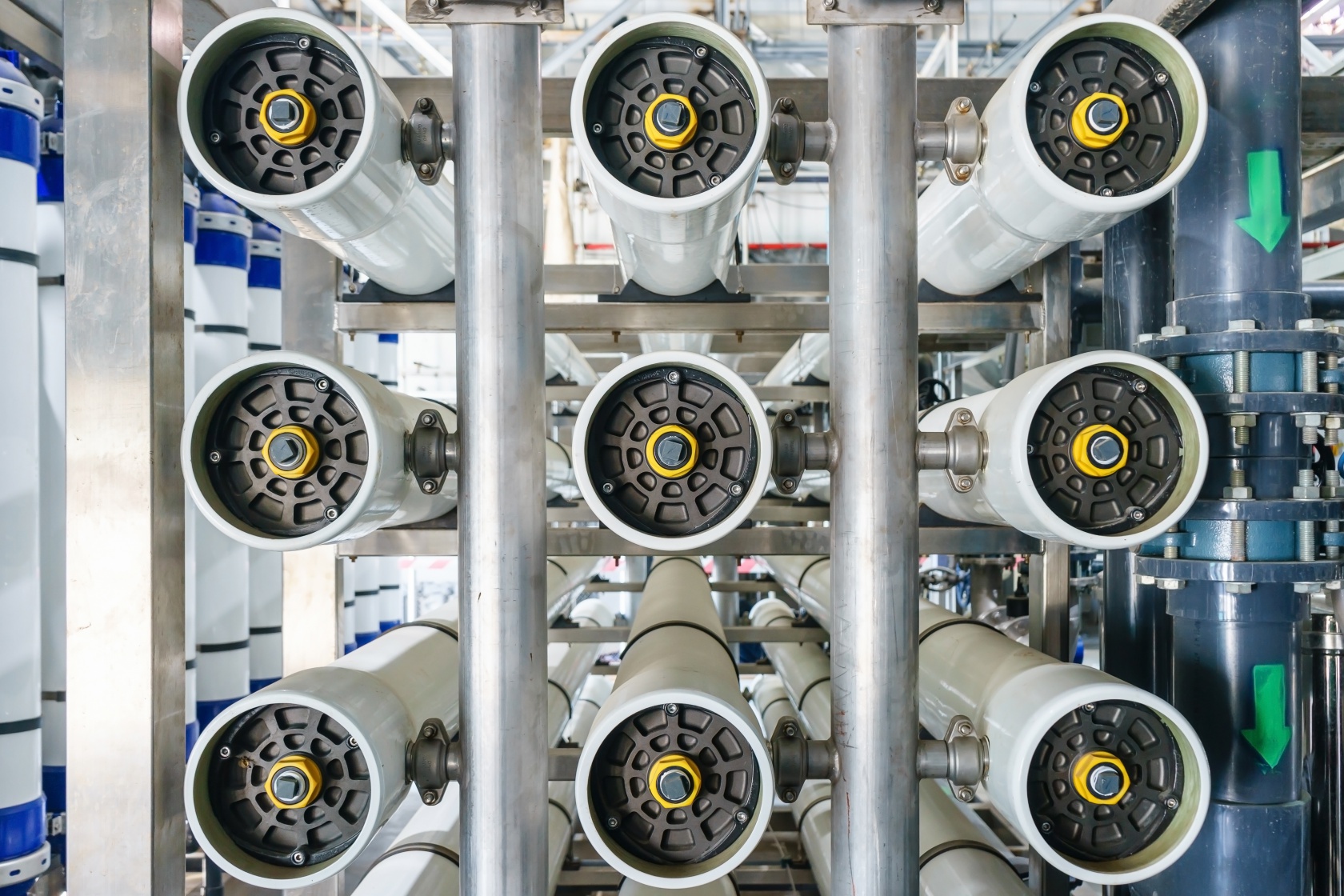

A basic principle of water treatment best practices is to start by ensuring that raw water quality is the best it can be before it enters the process or utility. Common impurities of concern include dissolved salts such as hardness, suspended particles and colloids), humic acids and microorganisms such as bacteria, fungi and multicellular organisms. In New Zealand, typical water sources can be characterised as having generally low to moderate hardness levels and high silica levels in volcanic regions. Ground water will often have elevated levels of iron and manganese. Surface waters can have high levels of suspended solids. A wide variety of mechanical treatments can be used to remove problematic impurities such as clarification, filtration, ultra-filtration and reverse osmosis. Chemicals can be used to enhance the performance of these mechanical processes, for example coagulants can be used alone or in conjunction with flocculants to boost in the sedimentation and removal of suspended solids.